TOGETHER TO ENVIRONMENTAL SUSTAINABILITY

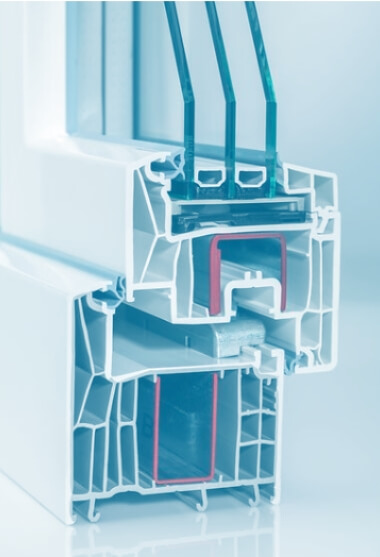

REHAU window profiles meet the highest standards. This is especially important for our co-extruded products, including those that are environment-friendly. Please note that the visible surface of the manufactured window meets the highest aesthetic requirements of the final consumer, and all the materials used meet the current EU standards (EN12608) and national quality standards, for example, the German RAL quality standard for uPVC profiles and the French CSTB quality standard .

Profiles manufactured by co-extrusion, as well as by monoextrusion, are regularly checked, in particular, by SKZ German independent polymer research center, and are subject to independent quality control. At the same time, both certain profiles and window profile systems are checked for compliance with standards (for example, certification according to RAL standards).

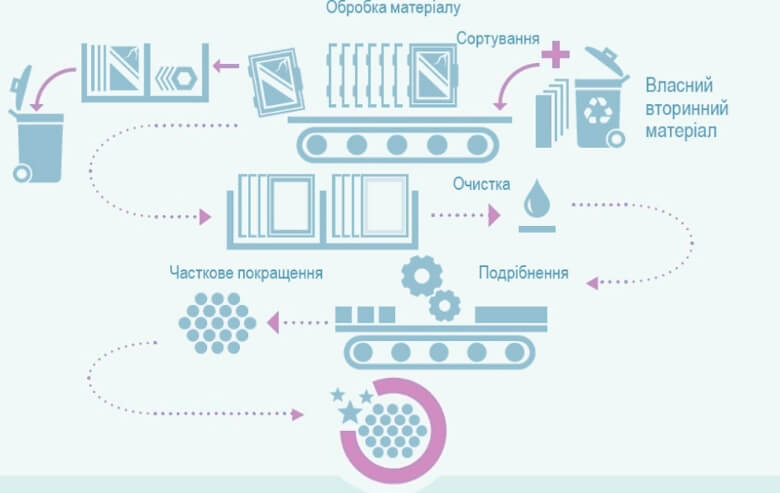

The REHAU concept of collecting materials for recycling was introduced in 1988 as one of the first in the polymer industry. We carry out a full cycle of qualified recycling of old uPVC windows and residues of profiles – the material is collected, cleaned, ground, sorted, improved and finally used again for the production of new window profiles.

Earlier, window profiles were produced mainly by monoextrusion using only the primary PVC.

By co-extrusion, i.e. multi-layer extrusion, the second extruder is used to produce the second material. So this process combines best characteristics of both materials.

The advantages of using recycled materials are obvious – the concept of recycling keeps valuable materials in production cycle and, even at the end of the first life cycle of the material, allows its reuse for the production of similar products.

As the base material, we mainly use:

— materials for recycling that are accumulated during own extrusion or lamination processes;

– materials for recycling from our partners ‘ window productions;

– materials obtained during the recycling of old windows.

Secondary materials are used to produce the profile core. Modern technologies allow us to produce such profiles both white and colored, since the difference between the colors of the core and the outer layer of the profile in the finished window is completely invisible. In this way, we make a significant contribution to the preservation of the environment.

Please contact us for your next project, no matter how big or small, so we can provide you with competitive pricing. You will be very pleased with the pricing and end result